Selecting the Right Sampling Method for LSS Projects

There are different reasons why you would go for sampling.

If you are a Lean Six Sigma Green Belt or Lean Six Sigma Black Belt, or just an aspirant or a Quality Engineer, you will encounter several scenarios where you have to sample the data during data collection in the Measure Phase of DMAIC project.

Before selecting the right method for sampling, it’s important to understand why sampling needs to be done, what is the objective of the data collection and what are the expected outcomes from the data collected through sampling.

Data sampling saves a lot of time and effort in data collection. But it comes with certain risks of drawing wrong conclusions, from the data so collected through sampling. If these risks have to be minimized, then one of the things we need to ensure the right sampling method is adopted.

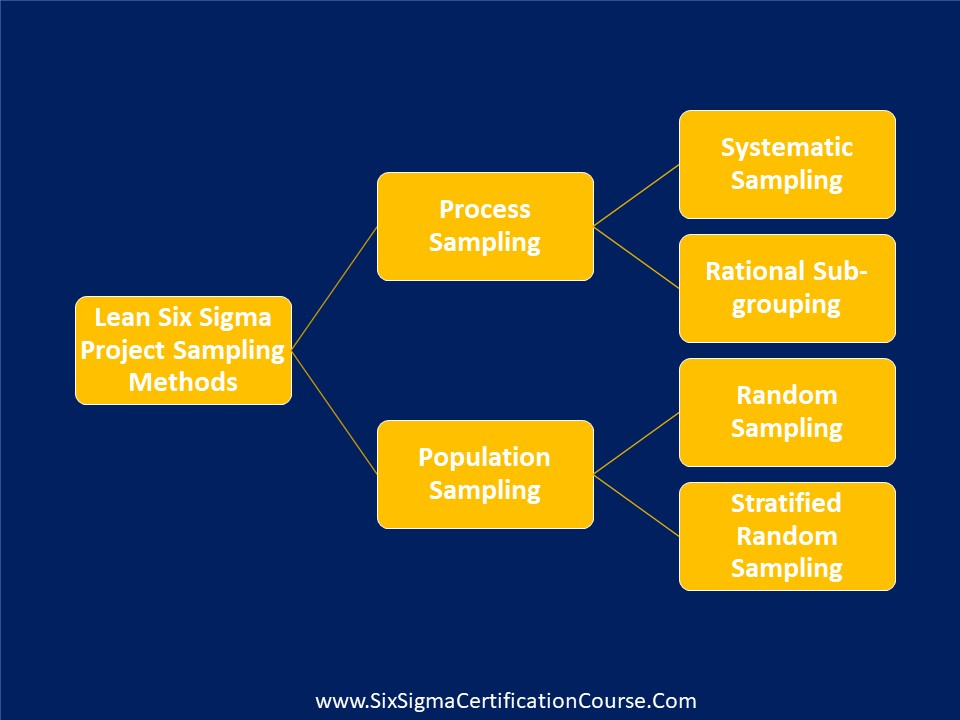

There are broadly 4 sampling techniques that are commonly used. There are few more intricate sampling techniques, but these 4 should suffice in most of the scenarios. We will now get to the details of selecting the right sampling method.

First understand if you are dealing with a Population or a Process in which sampling has to be performed. A population refers to a lot or collection of items which can be parts, documents, transactions, etc. but the population size is pre-defined. For example, if you have 100 applications, that becomes the population. If you wish to assess some characteristic of the 100 applications, then you can employ sampling, but the results will only be conclusive for those 100 applications. This is because we don’t have any idea of how this lot or population was built. (from one process or many)

On the other hand, when there is a process (manufacturing, service or tech) which is continuously producing output and you wish to sample in between the process steps or at the end of the process, so that you can check the health of the process and accordingly alter the process parameters, then you will deploy process sampling methods.

Thus as an example, if you have a lot of parts or applications to be processed, you can employ population sampling to evaluate incoming quality and process sampling to evaluate the quality of the output the process is generating. This concept will be very useful if you are running a Lean Six Sigma Green Belt or Black Belt project. In the Measure Phase of DMAIC, you will have to decide what data is to be collected and how this data collection will be executed. Depending on the nature of the problem or improvement you wish to bring about using Lean Six Sigma, the sampling method will have to be decided.

Once this is clear, the next step will be to decide exactly which method of sampling will you deploy. As mentioned earlier, broadly there are 4 methods of sampling, 2 in each Population Sampling and Process Sampling.

Random Sampling

This is the most common method of population sampling. For example, in your Lean Six Sigma Green Belt or Black Belt Project, if you wish to sample a few applications from a lot of 100 applications to find how many are incomplete, you can deploy this method.

Stratified Random Sampling

If your lot is not homogeneous but has different strata (or groups) within it, you will employ stratified random sampling. For example, in your Lean Six Sigma Green Belt or Lean Six Sigma Black project, if the applications are received through 3 different channels such as Physical Applications, Web Application Form and Applications from Mobile App, then its likely the sources of error are different and hence the error rates are also likely to be different. So we need to sample each strata separately and draw estimates depending on their contribution to the overall population. Hence in this case, it would be better to stratify the applications by source and then randomly sample within each strata.

Systematic Sampling

In case your Lean Six Sigma Green Belt or Black Belt project aims to improve any process, then you can employ process sampling there. For example, when applications are processed by a team of associates, you can conduct a dip-stick audit at regular intervals. This could involve collecting a few samples every hour. In case, you find that the error rates are increasing hour after hour, this information can help you to correct any deficiencies in the process right away. Hence this sampling method is useful not only for improvement projects using Lean Six Sigma DMAIC or PDCA but also for on-going process control and management.

Rational Sub-grouping

There is another process sampling method which you can employ in any Lean Six Sigma project, called as Rational Sub-grouping. If your process has no known patterns and consistently works in the same manner throughout the working cycle then, systematic sampling is sufficient. But if there are known patterns in the process, such as weekend, month end or even intra-day patterns such as morning, afternoon and evening patterns, then it may be wise for us to collect a few samples in every window of pattern. If there is unusually high variation within the samples collected in a given window, then that signals of some special cause of variation. For example, you expect errors to be lower in the morning, but when you sample 3 consecutive applications in the morning and find that 1 has low error but other two have very high errors, that indicates some underlying issue in the process. Thus, within sub-groups (for ex:within 3 samples of morning) we expect minimum variation while between sub-groups (between average of morning and evening samples), we expect significant difference, as such a pattern is naturally expected in this process. But if errors come out to be random, the variation between and within samples are no different, that either indicates the rationale for sampling is incorrect or something is wrong with the process.

Thus by using the above 4 sampling methods, you will be able to mitigate the risks associated with any Lean Six Sigma Black Belt or Lean Six Sigma Green Belt projects.

Tags

Floundering teams – A source of failure for six sigma projects… many can’t believe, but it’s true. Aptly ASQ has included this topic in their SSGB BoK.

The meaning of Floundering is to struggle or stagger clumsily as if confused. Floundering often results from a lack of clearly established goals, unclear tasks, discomfort with other team members, or due to overwhelming emotions.

Six Sigma projects often fail due to floundered teams. Project sponsors and Six Sigma Green Belts have to address such issues quickly, but they themselves are victims. This amplifies the problem and makes it one of the biggest failure modes for Six Sigma projects. If you aren’t convinced, consider the following:

- Usually six sigma projects are identified by senior leaders and Six Sigma Green Belt & team members are assigned. The strategic intent of the project may not be communicated to the team. They may just be aware of the project goal. This is the first and foremost source of floundering. Sponsor, champion, Six Sigma Green Belt and teams may be on the same page, when it comes to the goal, but beyond that there would be complete disconnect.

- Incorrectly scoped projects, often lead to incomplete or incompetent team composition and unreasonable goals. Both these factors lead to poor decision making, delays & fear of producing poor results.

- After all, when there is discomfort or no consensus among team members, it shows in their decisions, or their progression between tasks.

- Unlike IT projects, Six Sigma projects aren’t full time project engagements. Contribution is voluntary. As a result, the Six Sigma Green Belt exercises very little control over the team members and their participation level. This gives opportunities for negative team dynamics such as:

- Misunderstanding between team members

- Some team members bullying others

- Blabbermouths taking center stage and hi-jacking the main agenda

- Digressing and loosing focus

- Some teams are well organized and show no sign of floundering till it comes to improve phase. Execution might force some team members to dissuade, often leading to conflict and floundering

- The duration of the project and its scope itself can be major reasons for floundering. In today’s world of high attrition and frequent job rotations, longer the project duration, higher the risk of having new team members with different line of thought. There are also projects where the leader herself has changed.

- Sometimes, there could be floundering towards the end of a project too. Usually associated with the confirmation of results and computation of financial benefits on the process CTQ. Teams flounder when they are challenged by the financial approver on the real financial benefit.

Solutions

- Well defined roles of each team member gives more clarity, upfront

- Take up reasonable goals that enhances the confidence of team members rather than overwhelming them

- Reaffirmation of the project objectives time and again

- Regular (weekly) meeting of all team members to review the progress and assignment of work

- Division of labor among team members rather than riding on team leaders efforts

- Monthly presentation to sponsor on progress and course correction

- If the Six Sigma Green Belt notices that some team members are stretched, she needs to act immediately. Speak to the concerned person, his supervisor or the project sponsor

We hope this resource Floundering teams – A source of failure for Six Sigma Projects will help manage your Six Sigma Green Belt projects effectively.

Tags

FMEA is performed to refine a solution just before its implementation, or at the beginning of a project; to investigate if there is a possibility for any anomalies or risks arising during the process. In simple words, FMEA is a plan to lessen or eradicate risks associated with the process or proposed solutions. It is not only applicable in a Six Sigma project, but also in any IT project management and general purpose risk analysis/risk management.

Any anomaly or element can be considered as risk depending on the severity of its impact, frequency of occurrence of its cause, or the incapability of the control system to detect a cause. A risk rating called Risk Priority Number (RPN) can be used as a yardstick to prioritize and proactively mitigate risks; and to create the required focus within the organization to deal with risks. It is calculated as the product of the severity of the effect, into the occurrence of the root cause, into the detection of root cause.

- Severity is a rating that represents the seriousness of the effect(s) of the potential failure mode on customers or business – the more the severity, higher is the rating.

- Occurrence is a rating that represents the likelihood or frequency of occurrence of a specific cause – the more often it occurs, higher is the rating.

- Detection is a rating that represents the ability of the current control mechanism to detect or report occurrence of the cause – lower the ability to detect a cause, higher is the rating.

While the overall objective is to mitigate risks with high RPN, there can be multiple different strategies to do so. We can use 4 such strategies in the following order.

The 4 strategies for FMEA that can help you quickly reduce the overall risk rather than flounder.

Strategy 1 – Reduce the occurrence of cause

In a FMEA, consider all the high RPN items, and select the ones with high Occurrence rating. If the occurrence rating is high, then by reducing the frequency of occurrence of cause, you will reduce the number of times failure occurs. This is the most apt and best strategy to adapt as it directly addresses the core issue. However, situations may warrant you to consider other strategies.

Strategy 2 – Reduce impact of failure mode

In a FMEA, if we don’t have high occurrence ratings, then consider all the high RPN items and select the ones with high Severity rating. These are the ones that will create maximum negative impact on a customer, their business, and thus in fact on your business too.

By reducing the impact of the effect, you can show the immediate visible impact to customers. Particularly, if there have been escalations from customers, then this strategy will be best suited.

Strategy 3 – Improve the ability to detect risk

In a FMEA, when above strategies aren’t relevant, consider all the high RPN items, and select the ones with high Detection rating. Improving the detection mechanisms means that we have timely information to prevent the cause, or at least contingency, or mitigation.

Conventional risk planning usually focuses on this strategy as first priority.

Strategy 4 – Combination of all three strategies

If all three ratings are high & none of the above can be applied in isolation, then see if they can be combined & applied.

By following the above 4 strategies in a FMEA, we can systematically and quickly reduce risk in any process or solution in Six Sigma Project.