Lean Six Sigma Project – A beginner’s guide is a series that explains how to run Lean Six Sigma projects in detail. The biggest benefit of combining Lean and Six Sigma is to deliver more value to customers and business. In order for a Six Sigma Green Belt to be successful with a project, they must know what’s to be done, and how to accomplish them! This guide is a step-by-step procedure to execute the 5 phases of a Lean Six Sigma project.

Lean Six Sigma improvement projects follow 5 phase DMAIC approach. A six sigma project is not an academic exercise, but its primary objective is to impact customers, business, and employees positively. Thus stakeholder buy-in and sponsorship are very important factors for its success. Every project should have at least one project sponsor (One sponsor is just fine, two is OK, but greater than that is undesirable). The project sponsor is usually the process owner or a senior management executive who is accountable for the overall project and its success. They take the lead in identifying the project & its objectives, and in team formation.

The team composition should be cross-functional. The sponsor also has to decide whether this Six Sigma project should be led by a Black Belt or Green Belt. Once identified, the respective Six Sigma Belt plays the lead role in the project. It is their responsibility to complete the project on time, and deliver desired results. Now, for the remaining part of this beginner’s guide, let’s assume that it is a Lean Six Sigma Green Belt Project.

The duration of a typical project should be between 3 to 4 months. The overall project plan for all Six Sigma improvement projects are mapped to Define, Measure, Analyze, Improve, and Control. There are defined deliverables for each of these phases which have to be accomplished before progressing further. At the end of each phase, a formal tollgate is used to stage a gate review by the sponsors. Various Six Sigma concepts and tools can be applied to progress and accomplish desired phase-wise outcomes.

In order to make sure the project meets the timeline, and set-out objectives; the Green belt and team members are to meet regularly. In addition to this, Six Sigma Green Belts are mentored by Black Belts or Master Black Belts.

In a nutshell, following are the broad outlines for each of the DMAIC phases of Lean Six Sigma Project:

- Define – Identify the project objective and define the problem to be solved

- Measure – Collect necessary data regarding the problem and establish current performance

- Analyze – Use the data collected to analyze and screen factors which are the root causes for a problem

- Improve – Identify suitable solutions to overcome the root causes

- Control – Implement the solutions and monitor its results

Next, as a part of this beginner’s guide, let’s understand how to accomplish the deliverable of the Define phase here. Next >>>

Tags

Design for Six Sigma (DFSS) is an approach that is part of the Six Sigma methodology, and it aims to develop products and services which operate at Six Sigma or above. What does this mean; and how is this approach different from implementing six sigma in existing products, services & processes? If you have read our articles What is Six in Six Sigma, and What is Sigma in Six Sigma; you will understand how Six Sigma is measured.

Every process performs at its designed and operating capability. For instance, consider the Indian traffic and transportation management system. A good measure of its performance is the number of deaths due to road accidents. There are several other measures, but for simplicity let’s just consider this one. This performance measure is called CTQ (Critical To Quality).

India has the largest number of deaths per year due to road accidents (Approximately 130,000 deaths per annum). If we were to commence a Six Sigma project to reduce the number of deaths, we would use DMAIC approach. We will identify root causes for this problem, and try to eliminate them with good and sustainable solutions. For instance, helmets and seat belts mandatory, enforcement of speed limits & drunken driving laws, additional traffic patrols, etc., may be few solutions we will implement.

By doing so, lets hypothetically assume that we have been able to reduce the number of deaths to 30,000 per annum, in 3 years’ time. However, we aren’t able to reduce it any further. This stage; when any process or system is delivering its best performance, is referred to as Process Entitlement.

However, 30,000 is still a high number and we want to bring it down to manageable double digits. So we have to discard our existing traffic & transport management system; and design a completely new system, from scratch, that will help us reach our target. Double digit fatality means we will operate well within Six Sigma level, considering our 1.2 billion population as a base.

Such a process of re-designing or newly designing any product, service or products is referred to as DFSS. Design for Six Sigma is defined as a Customer focused design approach used for creating products, services, and processes which will deliver Six Sigma Performance. Samsung products are a very good example of Design for Six Sigma.

In many fields like airline, surgery, automobile braking, etc., require processes to deliver Six Sigma at all times. For such systems, design for six sigma concept comes handy. The very first time products and processes are developed, they are designed to deliver Six Sigma performance.

Following are the key differentiators for DFSS:

- Understand customer requirements, and translate them to product performance measures.

- Design products, sub-systems, and processes to deliver Six Sigma performance.

- Design ‘first time right’ products and services.

- Innovative designs deliver Six Sigma performance, rather than existing designs.

- Optimize the design for usability, manufacturability, or serviceability.

While DFSS is a principle, there are different ways in which it can be put to use. IDOV and DMADV are popular approaches.

IDOV is a 4 step approach representing Identify, Design, Optimize & Verify. And DMADV is a 5 step approach representing Define, Measure, Analyze, Design & Verify.

Tags

Six Sigma has been a successful management approach, and a philosophy for many leading global enterprises. Let’s understand Six Sigma Process – in other words – Six Sigma Deployment Approach.

While the deployment of Six Sigma depends on several factors; the following approach explains Six Sigma process in its simplest form.

Six Sigma as a management discipline puts customer’s interest ahead of others. The process of gathering customer requirements is called as Voice of Customer (VOC). A good deployment program starts with VOC. Customer requirements directly translate into business performance standards. In Six Sigma and many quality management approaches, these performance standards are called as Customer Specification Limits.

Operational metrics and performance measures like KPIs are created based on customer requirements. Such operational measures or KPIs are called as Critical To Quality (CTQ) metrics in Six Sigma.

Output of existing processes is measured against customer requirements. This becomes a benchmark of performance. In Six Sigma, this step is called as Assessment of Current Process Capability.

In case an end-to-end process is not capable of consistently meeting customer requirements, and produces high volume of defects; it is taken up for improvement.

Process improvement approach used in Six Sigma is called as DMAIC. It is the acronym of Define, Measure, Analyze, Improve and Control: a 5 step improvement approach.

In this manner, Six Sigma aims to link Customers, Business Processes, CTQs and process improvement all together.

The real power of a Six Sigma Process is in consistently and iteratively following the above activities.

Thus, an organization following a Six Sigma Process:

- Systematically and regularly gathers VOC

- Measures its process capability

- Identifies improvement opportunities

- Uses DMAIC to improve its processes

Tags

Six Sigma & Project Management are two high trending topics of interest among professionals and organizations today. While Six Sigma is a management approach, project management principles instill the rigor of execution.

Whatever is the nature of your business, innovation is critical today. In order to survive competition and be the customers’ choice, you need to come up with really new products and services.

While the deployment of Six Sigma depends on several factors; the following approach explains Six Sigma process in its simplest form.

Six Sigma as a management discipline puts customer’s interest ahead of others. The process of gathering customer requirements is called as Voice of Customer (VOC). A good deployment program starts with VOC. Customer requirements directly translate into business performance standards. In Six Sigma and many quality management approaches, these performance standards are called as Customer Specification Limits.

Operational metrics and performance measures like KPIs are created based on customer requirements. Such operational measures or KPIs are called as Critical To Quality (CTQ) metrics in Six Sigma.

Output of existing processes is measured against customer requirements. This becomes a benchmark of performance. In Six Sigma, this step is called as Assessment of Current Process Capability.

In case an end-to-end process is not capable of consistently meeting customer requirements, and produces high volume of defects; it is taken up for improvement.

Process improvement approach used in Six Sigma is called as DMAIC. It is the acronym of Define, Measure, Analyze, Improve and Control: a 5 step improvement approach.

In this manner, Six Sigma aims to link Customers, Business Processes, CTQs and process improvement all together.

The real power of a Six Sigma Process is in consistently and iteratively following the above activities.

Thus, an organization following a Six Sigma Process:

- Systematically and regularly gathers VOC

- Measures its process capability

- Identifies improvement opportunities

- Uses DMAIC to improve its processes

Six Sigma & Project Management are two high trending topics of interest among professionals and organizations today. While Six Sigma is a management approach, project management principles instill the rigor of execution.

Whatever is the nature of your business, innovation is critical today. In order to survive competition and be the customers’ choice, you need to come up with really new products and services.

All it means is that your change management ability is a direct measure of your success. In other words, timely launch of new products/services in desired quality and price are going to determine your success; apart from the cultural change aspect. So whether you want it or not, good project management skills are essential in today’s business to survive and win. Without digressing on other pre-requisites of good project management, let’s focus on one of most important but rarely focused area.

There are several project management techniques and tools available, such as: CPM, PERT, and Critical Chain. Immaterial of the base on which these models are structured, out of my experience, everything finally boils down to predicting the time duration for a task and delivery as predicted.

In small organizations (less than 10 employees), it is more of coordination, multi-tasking, and communication that will determine if a task can be completed as predicted. But with organizations involving a few hundreds of employees, it is all about how resources and efforts are synchronized. There may be lack of knowledge of what is to be done next, on who owns which piece, how & when to escalate, and lack of clarity on authority & decision making. Additionally, unlike big organizations, smaller companies will have to manage with inexperienced and understaffed scenarios.

So to make life easy for everyone; if processes associated with project management such as supply chain management processes, finance processes, clearly defined inter-department service levels and authorities, etc., are established well; it will help the organization deliver projects in time. Isn’t this what ‘Process Orientation’ is all about!

Strong Process Orientation: one of the key foundations of Six Sigma is responsible for success in most project based industries. Mathematically also it makes sense to focus on process orientation. For instance, consider the PERT model in which the PERT Time (Task duration) is a function of Optimistic Time (OT), Most Likely Time (MLT), and Pessimistic Time (PT). When OT and PT are wide apart, it means that it is not possible to predict the task duration accurately. In other words, the process on which the task is dependent has high variation. Such a process leads to higher PERT Time. When all the tasks of a project have widely spread OTs and PTs, the overall project duration itself will be high and unpredictable.

Tags

Have you ever thought about this before – Will Six Sigma help me become a better leader? Isn’t leadership a soft skill unlike Six Sigma? Six Sigma is more about playing with numbers, statistics, Minitab!!!

Ask leaders of organizations that follow Six Sigma as a management philosophy, and they will disagree.

A true practitioner of Six Sigma is a great leader. All basic principles of Six Sigma help to be a better leader:

- Customer Centricity

- Data or Fact Based Decision Making

- Strong Process Orientation

- Structured way to improve, design and sustain processes

Let’s consider 4 important dimensions of leadership that most world class organizations strive to instil in their associates.

- Ability to grow the business

- Capability to lead the team to deliver

- Drive culture of execution

- Conviction to sustain the momentum & optimism

Let us consider one at a time, and understand how Six Sigma can help focus on these 4 aspects.

Ability to grow the business

- Deep and broad business perspective is the first and foremost pre-requisite for any leader to growth their business. They have the ability to fragment or aggregate processes/tasks, and develop a meaningful understanding. Good leaders are quick to break complex processes into simple & small units, and manage them effectively. We call this ability as Strong Process Orientation in Six Sigma.

- Good leaders challenge the status quo, and thereby reinvent the business. Availability of information & factual data empowers a leader to take bold decisions.

- Businesses that are customer centric grow faster . Moreover customer requirements constantly change. Ability to choose the right method to reach out to customer, ask the right questions and present the data appropriately is the key. In other words, good leaders take additional care to establish and manage Voice of Customer programs.

- Customer retention and repeat business is all about instilling higher internal standards and practices to make processes error-free or defect-free.

Capability to lead the team to deliver

- In order to retain great talent, a leader should be able to align functional goals to individual’s KPI’s. They should use data to differentiate high and poor performers rather than intuition and gut feeling.

- A good leader’s ability to communicate crisply and candidly is only possible when they are data centric.

Drive Culture of Execution

- Results need to consistent. Great leaders manage variation along with averages. One of the primary goals of Six Sigma is to reduce Variation.

- Data or fact based decisions result in high probability of success. This means more confidence about the team and better alignment.

Conviction to sustain the momentum & optimism

- Constantly raising the bar is possible when one understands the CTQs, key drivers of the business, and process capability very well.

- Displaying personal courage cannot come without confidence. And confidence comes only with data.

So a good leader will not miss a single opportunity to apply the above principles of Six Sigma in their business to deliver results consistently.

That is why at many world class organizations, Six Sigma is in the fabric of who they are. So, beyond doubt, Six Sigma help me become a better leader!

Tags

Ask leaders of organizations that follow Six Sigma as a management philosophy, and they will disagree.

- Customer Centricity

- Data or Fact Based Decision Making

- Strong Process Orientation

- Structured way to improve, design and sustain processes

Let’s consider 4 important dimensions of leadership that most world class organizations strive to instil in their associates.

- Ability to grow the business

- Capability to lead the team to deliver

- Drive culture of execution

- Conviction to sustain the momentum & optimism

Let us consider one at a time, and understand how Six Sigma can help focus on these 4 aspects.

Ability to grow the business

- Deep and broad business perspective is the first and foremost pre-requisite for any leader to growth their business. They have the ability to fragment or aggregate processes/tasks, and develop a meaningful understanding. Good leaders are quick to break complex processes into simple & small units, and manage them effectively. We call this ability as Strong Process Orientation in Six Sigma.

- Good leaders challenge the status quo, and thereby reinvent the business. Availability of information & factual data empowers a leader to take bold decisions.

- Businesses that are customer centric grow faster . Moreover customer requirements constantly change. Ability to choose the right method to reach out to customer, ask the right questions and present the data appropriately is the key. In other words, good leaders take additional care to establish and manage Voice of Customer programs.

- Customer retention and repeat business is all about instilling higher internal standards and practices to make processes error-free or defect-free.

Capability to lead the team to deliver

- In order to retain great talent, a leader should be able to align functional goals to individual’s KPI’s. They should use data to differentiate high and poor performers rather than intuition and gut feeling.

- A good leader’s ability to communicate crisply and candidly is only possible when they are data centric.

Drive Culture of Execution

- Results need to consistent. Great leaders manage variation along with averages. One of the primary goals of Six Sigma is to reduce Variation.

- Data or fact based decisions result in high probability of success. This means more confidence about the team and better alignment.

Conviction to sustain the momentum & optimism

- Constantly raising the bar is possible when one understands the CTQs, key drivers of the business, and process capability very well.

- Displaying personal courage cannot come without confidence. And confidence comes only with data.

So a good leader will not miss a single opportunity to apply the above principles of Six Sigma in their business to deliver results consistently.

That is why at many world class organizations, Six Sigma is in the fabric of who they are. So, beyond doubt, Six Sigma help me become a better leader!

Six Sigma has evolved as a management discipline for improving processes, and providing customer delight. Some organizations like GE had adopted Six Sigma as their management philosophy.

So, Why Six Sigma? Why not follow other approaches like TQM, SCM, COPC, ISO, etc.

Let’s understand why many organizations choose Six Sigma over other approaches; and how they benefited.

There are 3 key salient features of Six Sigma that are noteworthy:

- Customer Centricity

- Process Orientation

- Fact Based Decision Making

Customer Centricity

While the emphasis on building business processes to meet customer requirements was first proposed by Joseph Juran & Edward Deming (fathers of modern Quality movement); it was taken seriously only with the advent of Six Sigma. Gathering the Voice of Customer and translating these requirements into product features, aka Quality Function Deployment (QFD), were loosely used in TQM. Whereas, in Six Sigma Voice of Customers (VOC) is the starting point.

Operational measures and performance measures (KPIs) are built based on VOC. These measures are called as CTQ (Critical To Quality). Customers’ needs constantly change. Such changing needs mean that processes also need to adapt and evolve. Six Sigma enables achieving this adaptation. While creating a new product or service line; the entire system is built to meet customer requirements. Such an approach is called as Design for Six Sigma (DFSS).

Process Orientation

Six Sigma builds strong process orientation within the organization. In Six Sigma, virtually every department, activity, or task is perceived as a process in itself or process step. What does that mean? It means a lot!

Every process produces few outputs, and in turn; requires few inputs. Outputs are consumed by Customers (internal or external); and inputs are provided by Suppliers. Such visualization is called as SIPOC in Six Sigma. This helps organizations to move away from the mind-set of fixing people when things don’t work; to fixing processes. In order to improve the outputs of any process or department, its process steps and inputs needs to be improved, and sometimes suppliers need to be educated. People are never penalized in Six Sigma!

Traditionally many industries & functions are regarded as ‘people’ driven. For instance, industries such as Hospitality, Entertainment & most service lines and functions such as HR, Marketing, Sales, Admin. Six Sigma organizations treat these as just another process. As a result, the dependency on individuals is also reduced. Organizational silos are challenged and processes are simplified.

Driving strong process orientation across the organization has resulted in unbelievable tangible and intangible benefits to customers and organizations. GE is a pioneer in driving process orientation in its Financial Service businesses.

Fact Based Decision Making

Once organizations establish process orientation; access to data and factual information will increase. This presents the next big opportunity for organizations. Across levels, organizations are dependent on their managers to take right decisions. Most often, these decisions are punctuated by decision maker’s bias and personal intuition. Wrong decisions are costly and usually borne by the organization.

Six Sigma’s bouquet of tools enables data or fact based decision making. This means the overall management is much more efficient and accurate. DMAIC, an acronym for Define, Measure, Analyze, Improve and Control, is a method used for solving problems. There are over 50 qualitative and quantitative tools which are part of DMAIC. These tools can be applied in several stand-alone situations too. These tools enable data or fact based decision making.

At a personal level, an individual practicing Six Sigma over a period time is more efficient and effective than her peers. This has direct impact on career and growth prospects.

Thus Six Sigma is a powerful approach which is not only beneficial to organizations; but also to individuals.

If you are interested in Six Sigma Certification Courses, visit our products page. Click here

Tags

This is the second article in the series that will help understand ‘What is Six in Six Sigma?‘ If you haven’t already read our article ‘What is Sigma in Six Sigma‘, we would like to recommend that you first do so.

For now, let’s look into what is Six in Six Sigma.

Let’s get started by understanding Customer Requirement and Actual Performance.

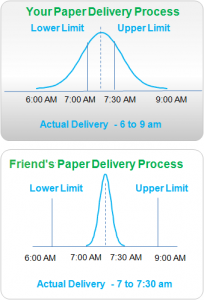

We are going to use the example of newspaper delivery everyday to your house. As a customer, you want newspapers to be delivered between 7:00 and 7:30 am (say within a half hour window). However, in reality, the paper gets delivered only between 6:00 to 9:00 am (a 3 hour window). So, in this case, the customer requirement or allowable variation is ’30 mins’ while the Actual Performance or Actual Variation is 3 hours.

On the contrary, your friend isn’t so particular about his newspaper delivery. He is in fact fine if they are delivered between 6:00 to 9:00 am (a 3 hour window). But in reality, his papers get delivered between 7:00 to 7:30 am (a half hour window).

How would you characterize these two situations?

- In your case, actual variation is much higher than allowable customer requirement. In ot

her words, Standard Deviation or Sigma is high.

her words, Standard Deviation or Sigma is high. - In your friend’s case, actual variation is much lower than allowable customer requirement (and so, Standard Deviation or Sigma is low)

Now, let’s answer the question ‘What is Six in Six Sigma?’

Six refers to the Sigma Capability of any process. In this case, the newspaper delivery process. When it’s Six, it means that the Standard Deviation or Sigma is so small that 6 Standard Deviations or 6 Sigmas can be fitted on either side of the bell-shaped curve. Based on the principle of bell-shaped curve (normal curve), 6 Sigma equals only 3.4 defects per million opportunities. For the newspaper example, it means that if there are 1 million days of newspaper delivery, only on 3.4 days (i.e. 3 or 4 days) of the delivery will be beyond your requirement. So, it is very obvious that your newspaper delivery isn’t at the Six Sigma level, but your friend’s delivery could be. It depends on the value of Standard Deviation. We covered the computation of standard deviation in ‘What is Sigma in Six Sigma’.

Let’s say for your friend’s process, only 5 standard deviations or sigmas can be fitted on either side of the bell-shaped curve, then, his sigma capability is at 5 or his newspaper delivery process is at 5 Sigma.

To sum up, if you want a particular process to be at Six Sigma, then you will have to manage the following:

Understand what the customer requirement is? If there is a window within which the customer wants her delivery or quality, then that becomes your customer requirement.

- Use the data of process performance to compute the standard deviation.

- Assess if the Standard Deviation or Sigma of the process is small enough, that 6 Sigmas can be fitted on either side of the customer requirement window.

- Let’s say your process isn’t at Six Sigma then to find out the sigma value you can either use Sigma Capability Table, Normal Distribution Table or Sigma Calculator. Details of how to compute Sigma for any process is covered in detail in our Six Sigma Green Belt Course.

Tags

First time, I ever heard the term Six Sigma, I was puzzled, lost and obviously amazed. Here was a term that I couldn’t make out a bit. I felt exactly the same when I first heard H2O from my primary school science teacher.

By the way, what is Sigma in Six Sigma? That’s the next question that I wanted someone to answer. The Six Sigma Black Belt who introduced this term to me in a training, gave a very complicated answer, which confused me further. In those days, Google didn’t exist, so I flipped many pages of our company’s Six Sigma manual, and then couple of statistics books, but I finally reconciled.

Sigma is the Greek alphabet (in small letters), which is used to represent ‘Standard Deviation’.

Sigma (standard deviation) has been in existence since the days of Gauss, who found out the bell shaped curve. But it has become very popular after Motorola coined the term Six Sigma. Now, this methodology has evolved into Lean Six Sigma.

Without complicating things for you, Standard Deviation is a measure of variation that exists in any process.

The term variation itself is very simple to understand. For example, if your morning newspapers arrive between a time window of 6 to 9 am, while your friend’s newspapers arrive between 7 to 7:30 am, then your ‘newspaper delivery process’ has high variation compared to your friend’s.

So, let’s learn standard deviation in layman’s language, so that we can understand what is sigma in Six Sigma in practical sense.

Standard Deviation is the average distance of all the data points from their average.

Let’s consider the time when your newspaper gets delivered, for a week : Mon – 6:30 am, Tue – 7am, Wed – 6:45 am, Thur – 8 am, Fri – 6 am, Sat – 8:30 am, Sun – 9 am.

For this data, the average time when newspaper gets delivered is 7:23 am. So some days delivery is before this time and some days after.

Next, you compute the difference between each day’s delivery time and average time for all 7 days, i.e, for Monday : (6:30 am – 7:23 am ) = – 0:53 minutes, and likewise for all values.

Now, we need to calculate the average of all these differences. But the differences you compute will have both minus and plus values. If we add them as such, they will nullify. That wouldn’t work. So, we use the following approach.

- Square all the differences. By doing so, all minus signs will become plus, because (minus x minus = plus) and (plus x plus = plus).

- Now add all the squared differences.

- Divide them by total number of days of data you collected. In this case, it is 7.

- Whatever value you get is already squared, so we have to find its square root.

Finally, the value you get after finding the square root, is the Standard Deviation. For this example, standard deviation or Sigma turns out to be nearly 1 hour (precisely 62 mins). This means that your newspaper boy is on an average one hour ahead or behind than his usual delivery time of 7:23 am.

Coming back to our original question, what is Sigma in Six Sigma? So Sigma is a measure of variation in any process. Higher the sigma, higher is the variation, which is undesirable.

So, one could compare two similar processes for their Sigma values and find out which one is better. In this case, your friend’s newspaper delivery boy is better than your delivery boy!

This will give you a simple idea of What is Sigma in Six Sigma, but this is only understanding half the story. You still need to understand What is Six in Six Sigma in our next article.

Six Sigma Certification Course Team

Tags

All processes need a control or management mechanism to ensure that they meet or exceed customer expectations consistently. Process parameters that go out of control need to be restored back to their normal values. How fast this has to be done depends on the type of process. For a surgeon, he needs to restore parameters back to normal within seconds. Engineers working in processing plants like paint shops need to react within minutes. However, for some processes, a couple of hours or a couple of days would be good enough.

A process control or management plan, usually prepared in the control phase of a Six Sigma project, provides insights on a reaction or response plan.

A reaction plan or response plan specifies a course of action that is needed to be taken when process control parameters go out of control. And, it includes both immediate and long-term actions to restore a process performance to its desired level.

There are 5 different types of reaction plans that can be considered while creating a process control plan:

- A plan to continue the process with close monitoring: – A process needs to be closely observed to see where it is going wrong, what is causing the parameters to go out of control, and how often is it occurring; for example: the source of the noise level of a generator or machine. Therefore, at this point, continue to run the process but closely monitor it as well. It is indeed, a very low impact reaction plan, but this is good enough for many processes.

- Enforce a manual override: – If a system is running automatically, stop and run it manually in order to exert a little more caution. This not only helps observe which part of the process is failing, it also helps to get a better handling of the process.

- Follow special instructions: – The next thing to do, when out of control parameters have been identified, is to follow instructions that are kept in place; for example: in case of a fire, check the instructions to find the exits, etc. Therefore if instructions are followed, then it will help bring the process back on track.

- Stop and escalate: – If a process goes wrong, and none of the above actions work, only then we should stop a process and escalate it to the experts or concerned department.

- Stop, correct, and resume: – This action can be observed if a process goes wrong and none of the above actions work, and if there is an expert among us who can fix the issue. Then, we can stop the process, correct the process and continue the process; while observing if the process has been restored to its desired level of performance. This reaction plan will have a quick and immediate impact. For some critical processes, this reaction plan is very apt.

The concept of a reaction plan or response plan is not only applicable in control phase, but also for standalone situations. Be sure to follow the 5 steps or types of procedures that need to be observed in the event of a process going out of control.

Tags

Here are my observations based on not just training a few hundred Six Sigma Green Belts across different demographics of geography, industry and age group, but also having mentored them for few months after the training:

- Retention of a subject like Six Sigma is much less than soft-skills or technical training like software languages.

- Ability of Green Belts to relate the application of six sigma concepts to their line of business is quite lesser than soft-skills like team work, time management, negotiation skills, etc.

Here are the 10 things according to me that Six Sigma Green Belts forget within just 10 -days of attending a training program, implying nearly zero retention:

- Project Charter: How to a write a business case that convinces the management? And also differentiate it from Problem Statement.

- Fish-Bone: What to do after completing a Fish-Bone diagram? Of course, collect data but on what factors?

- Gage R&R: Conduct an live Gage R&R study (at least Discrete data).

- Sampling: Choosing a sampling scheme and deciding the sample size for data collection.

- Descriptive Statistics: Meaningful and practical interpretation of ‘Standard Deviation’. If there is a process with Standard Deviation of 5 minutes, what does this number mean in real sense?

- P-value: What does it mean to the business to accept or reject a hypothesis based on P value?

- Variation: Identify the major sources of variation that impact a project metric?

- Regression: How to use the regression equation to operate the business efficiently.

- Control Chart: Explain to a layman (probably a Manager) what an out-of-control data point means in practical sense.

- Sustenance: How to make sure the project exists after a year. I don’t mean the project deck! Many times, it is considered that sustenance is not in our hands, but actually it is a skill that can be acquired and needs to be taught to all Green Belts.

One of the primary reasons, why Green Belts can’t retain these 10 things, is because most of all this is taught in less than a week with little time for things to settle in, and for the participants to relate.

One of the solutions, that works well for me as a coach, is to limit the class size to 2 or 3 and spread the program over 60 days. I actually found best results during my one-on-one training sessions!

Return-on-Investment of such executive development programs are at most important and so the business & career benefits recoups these investments.

My note will be incomplete if I don’t mention about few things that Six Sigma Green Belt retain very well after the training, even for several years:

· How to do Fish-Bone Diagram?

· How to play the Gage R&R game?

· Remember and recite the phrase “P is low, Null must go”

· How to map the process?

· What is Value Add, and Non-Value Add?