Tags

Tags

Tags

Tags

Have you ever confronted a situation doing hard work the whole day and at the end you realize that most of the time had been given by you and your team to the Non Value Added things!

One of the important aspects of the leadership in today’s competitive world is Prioritization. It helps to save time and money as you will be able to focus on what is important at the expense of lower value activities. Prioritizing skills are your ability to see what tasks are more important at each moment and give those tasks more of your attention, energy, and time.

We all have so much on hand to do and really speaking so much time to finish the things up. But we lack the skill to manage our work with the time. We mostly forget to take up the important things first and less significant work later. Instead, we do completely opposite to this. This is human nature as we all do the same thing in our day to day lives.

This issue is pertinent not only at an individual level, but even at organizational level. Organizations focus on the wrong reasons or causes and waste a lot of effort to solve a problem or improve their business.

How to improve upon it?

Lean Six Sigma teaches a very useful technique of prioritization to overcome this problem which is a mother of our all the other problems.

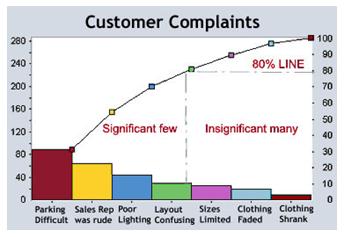

Pareto Analysis is based on 80/20 rule which says that our 20% efforts (out of the whole 100%) will give 80% of the benefits. This can be interpreted in many different ways like, for sales people 80% of the orders will come from the 20% of the customers, for team managers 20% people of the whole team shall give 80% of the work or results. Here, we should keep in mind that this doesn’t mean that the rest 20% is not important at all but can be said as less significant.

To generalize, 80% of the problem is caused by 20% of the reasons!

Thus using the Pareto principle, we can derive maximum impact with minimum effort and within short time span, if we focus on the right factors. Simple it is, right?

Before understanding the benefits of Pareto Analysis there are certain facts to be known about it. They are as under:

- This principle was developed in the year 1896 and is named after Vilfredo Pareto who was an Italian engineer, sociologist, economist, political scientist, and philosopher.

- Pareto derived this concept by his work and experience and observed that 80% of the wealth in Italy belonged to 20% of the people.

- In the year 1941, Dr, Joseph Juran who was an evangelist of quality and quality management as he was an engineer and a management consultant cam across the concept of Pareto Principle. He then started applying the principle in the quality and derived a phrase through experience that is “there are vital few and useful many”.

- The Pareto Principle can be implemented in many different aspects such as in science, management, business, in software, in sports, occupational health and safety, financial service industry, and implementing projects which says that put 80% of your time in 20% of your project which will save a lot of your time and energy.

- Pareto principle can be graphically represented by Pareto Chart that contains bothbars and a line graph, where individual values are represented in descending order by bars, and the cumulative total is represented by the line.

With an example given as under you will be able to understand why to focus on significant few:

Our Online Lean Six Sigma Green Belt Certification course teaches you step by step procedure to construct a pareto chart, different pareto variants and how to interpret them. More importantly it covers when and when not to apply pareto principle.

Benefits of Pareto Analysis:

- Improved Decision Making: With a focus on resolving problems, the procedures and processes required to make the changes should be documented during a Pareto analysis. This documentation will enable better preparation and improvements in decision making for future changes.

- Increased Efficiency: Once the changes or problems are listed, they are ranked in order from the biggest to the least severe. The problems ranked highest in severity should become the main focus for problem resolution or improvement. Focusing on causes and problem resolution contributes to organizational efficiency.

- Enhanced Problem Solving Technique: Members of a group can conduct a Pareto analysis together. Arriving at a group consensus about the issues that require change fosters organizational learning and increases group cohesiveness. Lean Six Sigma Green Belt Certification course shall help the individuals of the company learn many tools along with Pareto Analysis which shall also help him or her to boost their careers.

- Saves Time and Money: Doing right things at the right time with right people and at the right place is naturally going to save time and money and this has to be calculated by multiplying the time with the number of individuals involved in the process.

Tags

If you are new to Lean Six Sigma then Y=f(X) is one amongst many jargons that you will have to familiarize yourself.

The objective of Lean Six Sigma philosophy and DMAIC improvement methodology is to identify the root causes to any problem and control/manage them so that the problem can be alleviated.

Six Sigma is process oriented approach which considers every task as a process. Even the simplest of the tasks, such as performing your morning workout or getting ready to office is considered as a process. The implication of such a view point is to identify what is the output of that process, its desired level of performance and what inputs are needed to produce the desired results.

Y is usually used to denote the Output and X for the inputs.

Y is also known as dependent variable as it is dependent on the Xs. Usually Y represents the symptoms or the effect of any problem.

On the other hand, X is known as independent variable as it is not dependent on Y or any other X. Usually Xs represents the problem itself or the cause.

As you will agree that any process will have at least one output but most likely to have several inputs. As managers, we all are expected to deliver results and achieve a new level of performance of the process such as Service Levels, Production Levels, Quality Levels, etc., or sustain the current level of performance.

In order to achieve this objective, we focus our efforts on the output performance measure. However a smart process manager will focus on identifying Xs that impact the output performance measure in order to achieve the desired level of performance.

How does one identify the input performance measures or Xs?

Six Sigma DMAIC methodology aims to identify the inputs(Xs) that have significant impact on output (Y). After that the strength and nature of the relationship between Y and Xs are also established.

Six Sigma uses a variety of qualitative and quantitative tools & techniques listed below to identify the statistical validation of the inputs (or root causes), their strength and nature of relationship with Y:

- Cause and Effect Diagram/Fish Bone diagram

- 5 Why Analysis

- Process Maps

- Histogram

- Descriptive Statistics

- Run Charts

- Normal Distribution Plots

- Box plots

- Stem and Leaf Plots

- Hypothesis Testing

- ANOVA (Analysis of Variance)

- Chi-Square Test

- 1-t Test

- 2-t Test

- Paired t Test

- Correlation

- Regression

- Scatter Plots

- Statistical Process Control (SPC)/Control Charts

What does f in Y= f(X) mean?

‘f’ represents the nature and strength of the relationship that exists between Y and X. On one hand, this equation can be used for a generic interpretation that symbolizes the fact that Y is impacted by X and nature of relationship can be quantified. On the other hand, such a mathematical expression can be created provided we have sufficient data using the above mentioned analytical tools such as regression and other hypothesis tests.

The mathematical expression that we obtain is nothing but an equation such as:

TAT = 13.3 – 7.4*Waiting Time + 1.8*No. of Counters – 24*Time to Approve

Once such an equation is established, it can be easily used to proactively identify the Y for various values of X. Thus Y= f(X) is the basis for predictive modeling. All the newer analytical concepts such as Big Data, etc are based on this foundation principles.

Tags

Floundering teams – A source of failure for six sigma projects… many can’t believe, but it’s true. Aptly ASQ has included this topic in their SSGB BoK.

The meaning of Floundering is to struggle or stagger clumsily as if confused. Floundering often results from a lack of clearly established goals, unclear tasks, discomfort with other team members, or due to overwhelming emotions.

Six Sigma projects often fail due to floundered teams. Project sponsors and Six Sigma Green Belts have to address such issues quickly, but they themselves are victims. This amplifies the problem and makes it one of the biggest failure modes for Six Sigma projects. If you aren’t convinced, consider the following:

- Usually six sigma projects are identified by senior leaders and Six Sigma Green Belt & team members are assigned. The strategic intent of the project may not be communicated to the team. They may just be aware of the project goal. This is the first and foremost source of floundering. Sponsor, champion, Six Sigma Green Belt and teams may be on the same page, when it comes to the goal, but beyond that there would be complete disconnect.

- Incorrectly scoped projects, often lead to incomplete or incompetent team composition and unreasonable goals. Both these factors lead to poor decision making, delays & fear of producing poor results.

- After all, when there is discomfort or no consensus among team members, it shows in their decisions, or their progression between tasks.

- Unlike IT projects, Six Sigma projects aren’t full time project engagements. Contribution is voluntary. As a result, the Six Sigma Green Belt exercises very little control over the team members and their participation level. This gives opportunities for negative team dynamics such as:

- Misunderstanding between team members

- Some team members bullying others

- Blabbermouths taking center stage and hi-jacking the main agenda

- Digressing and loosing focus

- Some teams are well organized and show no sign of floundering till it comes to improve phase. Execution might force some team members to dissuade, often leading to conflict and floundering

- The duration of the project and its scope itself can be major reasons for floundering. In today’s world of high attrition and frequent job rotations, longer the project duration, higher the risk of having new team members with different line of thought. There are also projects where the leader herself has changed.

- Sometimes, there could be floundering towards the end of a project too. Usually associated with the confirmation of results and computation of financial benefits on the process CTQ. Teams flounder when they are challenged by the financial approver on the real financial benefit.

Solutions

- Well defined roles of each team member gives more clarity, upfront

- Take up reasonable goals that enhances the confidence of team members rather than overwhelming them

- Reaffirmation of the project objectives time and again

- Regular (weekly) meeting of all team members to review the progress and assignment of work

- Division of labor among team members rather than riding on team leaders efforts

- Monthly presentation to sponsor on progress and course correction

- If the Six Sigma Green Belt notices that some team members are stretched, she needs to act immediately. Speak to the concerned person, his supervisor or the project sponsor

We hope this resource Floundering teams – A source of failure for Six Sigma Projects will help manage your Six Sigma Green Belt projects effectively.