Most conventional organizations comprise departments and functions. A department head or functional head is responsible for all department deliverables. All department members should have clearly defined responsibilities for their respective tasks. Departmental tasks are expected to be performed on time and with quality. Every member of a department operates within a framework called a functional silo.

Functional silos focus on their own objectives alone and are not involved in interacting with other groups and sharing internal process information with others. Each department may also have several cross-departmental tasks that fall outside of the functional silo. Cross-departmental tasks can have delivery and quality issues. The boundary set up between functional and cross-departmental tasks brings about key challenges, including:

- Layers of bureaucracy that involve too many approvals.

- Lack of ownership in cross-departmental tasks.

- Management frustration due to lack of coordination among departments.

- Too many steps, such as checking and quality control, which are redundant for every department.

- Lack of focus on customers due to employee attention on internal tasks.

- And, opportunities for errors or corruption because of lack of ownership.

Cross-functional processes relate to a series of activities that are executed across an organization. Cross-functional processes are not organized by departments or functions, but by processes which comprise several departmental activities. In addition, cross-functional processes help clarify the end-to-end execution of a process. A cross-functional structure is a Six Sigma way of thinking how processes are structured and resources are aligned per key outputs. Therefore, a cross-functional structure facilitates better alignment to customer needs. Some of the benefits of a cross-functional process include:

- It becomes easy for top management to clarify its quality, cost, and delivery goals and deploy them to employees at every level.

- And, it facilitates close coordination among different departments in the organization.

Tags

QFD offers several benefits to organizations.

- It reduces design cycle time due to the decrease in design changes.

- It reduces the overall product development time because the focus is solely on satisfying key customer needs.

- It reduces overall cost by reducing design changes.

- It improves customer satisfaction because the development process is driven by the voice of the customer (VOC).

- It rates a product against other products in the market through competitor analysis.

- And, it documents identified competitive marketing strategies.

Tags

Quality Function Deployment (QFD) is a structured approach followed by customer-driven organizations to transform customer requirements into their product specifications.

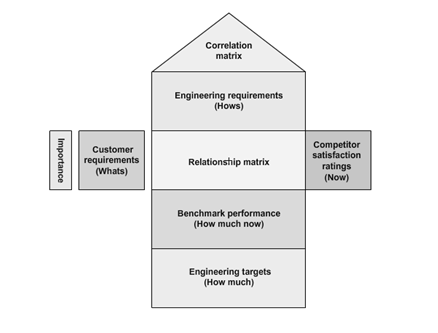

The House of Quality (HOQ) is a diagram used by a product development team during the initial stage of the QFD process.

It uses a planning matrix to define the relationship between customer requirements and the capability of the product and the company to satisfy these requirements. Because this matrix looks like a house, where customer requirements and product attributes resemble the main living quarters, competitive analysis resembles the porch, and the correlation matrix resembles the roof, it is called House of Quality.

HOQ encompasses different QFD elements used for understanding customer requirements and aligning business processes to meet these customer requirements.

It starts with customer requirements. The customers for a product or service are identified and their requirements from the product or service are gathered using different tools such as focus groups, surveys, and customer experiences. A structured list of customer requirements is then drawn by analyzing and organizing this data using tools such as affinity diagrams and tree diagrams.

Importance ratings are used for quantify the customer requirements and rated according to their importance on a scale of 1 to 5. This rating will be used in the relationship matrix at a later stage.

Another element is the Competitive analysis where customers views about the competition are gathered through research to provide a better understanding of the market. Here, the customers rate an organization’s products or services against competitors’ products or services. Also, Technical requirements that are not known to customers are identified and documented. These requirements generally stem from management or regulatory standards that a product must meet.

Relationship matrix defines the relationship between customer requirements and an organization’s ability to meet those requirements is determined. The relationship between the two factors is classified as weak, moderate, or strong and given the values of 1, 3, and 9, respectively. Even, in Importance weighting rating, Customer requirements are weighted according to their importance for defining and prioritizing key criteria. The relative importance of customer needs and the company’s and competitor’s performance are taken into account while calculating this. Target values for each product or service attributes, known as technical descriptors, that can be used as benchmarks against competitors’ target values are established. These target values are the “how much” of these product or service attributes.

The technical descriptors are compared with the competitors’ technical descriptors using scientific analytical techniques to assess their properties is called Engineering analysis. This also includes reverse engineering competitors’ products or services to determine the values for their technical descriptors. Correlation matrix is the relationship among customer requirements are analyzed to identify correlated requirements. The relationships are then ranked for determining areas of improvement that need to be focused upon.

Tags

DFSS and DMAIC are two of the methodologies commonly used by organizations to implement. Six Sigma. Organizations with well-developed Six Sigma programs also run DMAIC and DFSS projects concurrently.

| Feature | Description |

| Focus |

|

Tags

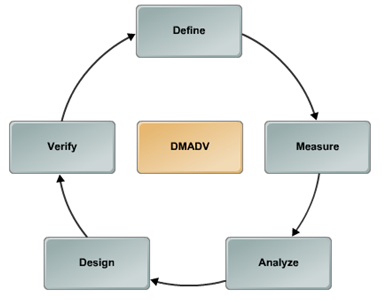

Another roadmap of DFSS is DMADV, an acronym for five interconnected phases, namely Define, Measure, Analyze, Design, and Verify. This methodology is used in projects that involve creating a new product or process design.

Define – The project goals are defined so that they are in line with customer requirements and enterprise strategies.

Measure – Characteristics that are critical to quality as well as product and process capabilities are measured.

Analyze – The different process options are analyzed and the best process that is consistent with customer requirements is selected.

Design – The details of the process are designed and optimized to meet the needs of customers followed by the performance of the new design which is tested through pilot runs before implementation.

Verify – In this phase the results are test and implementation of new design is carried out for large scale deployment.

Tags

In the Define phase, the Six Sigma team in a software product development company found that customers identified many issues in the beta version of its software.

However, if all the issues raised were to be fixed, timelines would slip and the budget would increase. The team then calculated the number of changes and the time and budget required for fixing these issues in the Measure phase.

In the Analyze phase, the team determined if the changes were aligned with the scope of the project and then identified changes that should be made. It also identified conflicting changes pointed out by the reviewers, communication gaps between the developers and the customers, and ways in which changes were communicated to the developers as other major causes of the issues.

In the Improve phase, the Six Sigma team took several steps, such as determining the limitations of the software, having regular meetings with customers, identifying the appropriate application to communicate the changes to the developers, creating change requests, and monitoring the implementation of the approved changes until closure to eliminate the issues.

Finally, appropriate mechanisms were set up in the Control phase to monitor the regularity of meetings and communication between the developers and customers as well as to monitor the performance and usage of the change request feature.

Tags

A value-added activity is any activity that increases the worth of a product or service. It directly contributes to meeting customer requirements, and customers are willing to pay for it. Value-added activities also generate a positive ROI for an organization. Without these activities, the process will be affected. A lean team should analyze if activities in a process actually add value to a product or service. They should also determine if activities in a process can be performed in parallel or be merged. This will help organizations deliver outputs more efficiently.

Example: In a manufacturing process, value-added activities can include: receiving a part request, preparing an internal request for a part from production, finding a relevant plant for issuing a request, finding production availability, updating part request information, and the manager processing the part request information and updating the request.

Non-value-added activities are activities that consume resources and time without adding any value to a service or product. Non-value-added activities do not contribute to customer satisfaction and, therefore, customers are not willing to pay for these activities. They are not important to the production and delivery of a product or service, and eliminating them will not affect a process. Because non-value-added activities do not generate any positive ROI but incur only expenditures, organizations should focus on eliminating them.

Example: In the manufacturing process, non-value-added activities can include: sorting and organizing requests, searching for relevant part production locations, checking locations for availability and delivery, generating production requests, and reviewing the status of requests.

Tags

Total Quality Management (TQM) is a structured system focused on satisfying customers by involving all members of an organization in improving the quality of products, processes, and resources. Sustained customer satisfaction, its main objective, is accomplished through systematic methods for problem solving, breakthrough achievement, and standardization derived from teaching quality leaders such as Philip B. Crosby, W. Edwards Deming, Armand V. Feigenbaum, Kaoru Ishikawa, and Joseph M. Juran. There are no hard-line procedures for implementing TQM. The PDCA cycle, also known as the Shewhart Cycle or the Deming Cycle, is a popular TQM problem-solving tool.

(more…)Tags

Six Sigma is a combination of the best elements of various quality improvement methodologies and a rigorous statistic-driven approach to performance improvement. The term “Six Sigma” was coined by Bill Smith, an engineer at Motorola. Six Sigma, in the present form, originated in the early 1980s at Motorola as a tool for reducing product-failure levels by 10 times in five years. General Electric (GE) implemented Six Sigma in 1995 after Motorola, and Allied Signal followed the Six Sigma trail after GE.

Six Sigma methodology evolved by combining the best elements of earlier quality improvement innovations.

|

Innovation |

Description |

| Uniformity system |

|

| Moving assembly line |

|

| Control charts |

|

| Quality movement |

|

| Customer Centric Products |

|

| .Zero defects |

|

| Quality standards |

|

| Six Sigma |

|

Tags

Six Sigma is a customer-focused approach to business process improvement and performance management which encompasses a statistical and method-driven process. In order to effectively deploy the process in your organization, it is necessary to identify the basic elements that drive the Six Sigma methodology. Knowledge of the Six Sigma fundamentals is the first step toward a successful Six Sigma implementation. Before applying any business strategy in an organization, you must identify the goals and benefits of the strategy. You must also recognize the need for such a business strategy in the organization.

Surviving in a business world that is full of competition is crucial to any organization. Six Sigma provides the means to handle declining product prices in the market, which helps any organization compete with the best companies in business. It targets zero defects by setting a common performance goal for the entire organization. Six Sigma helps an organization achieve increased profitability and quality improvement rates, ahead of any of its competitors. Reduced scrap-related costs, rework, improved yield, and increased customer satisfaction are identified in companies striving to achieve Six Sigma.

A Six Sigma initiative differs from other quality improvement methodologies because it ensures that the costs involved in implementation are offset by the gains received from improvements.

The primary goal of Six Sigma is to implement a measurement-based strategy in an organization that concentrates on process improvement and reducing variation. In addition to this, the other important goals of Six Sigma include:

- Reducing the number of defects, leading to the improved quality of a product or service.

- Achieving customer satisfaction by ensuring that customer expectations are met.

- Reducing cycle time, which enables the faster delivery of products.

- And, higher profitability by improving efficiency and effectiveness of the organization.

Tags

In a Continuous improvement journey, improvement projects are nothing but the lifeline. In this series of articles, we covered on the Need for Project Selection and the Criteria for project. Now we’ll answer the big question – Where can I get my projects from? Essentially various sources of the project!

- Customers Interactions: “Customers” are the biggest source for improvement projects. Classically, negative customer sentiments are good places to start. Your customers are unhappy, so it’s time to fix the issue. Mixed or ambiguous sentiments are also relevant places to start.

- Customer Complaints:If your organization has a list of customer complaints, then that is an apt place to commence. Complaints are not only sore for your customers, but for you too. Such complaints may cover a vast product or service attributes such as product or service quality, delivery time, responsiveness, people issues, pricing or areas of monetary impact including warranty claims,process & policy issues.

- Repeat Complaints: You can go one step further and target repeat complaints instead. Repetitive complaints from the same customer with the same tagging indicates high priority area for improvement.

- Enquiries & Requests: Few organizations target the need of customers to call or contact the organization and, reduce them. It might not be a complaint, instead just an enquiry or request. In other words, interactions with the organization that can be avoided. Looking at enquiries and requests serve as a proactive means to identify future problem areas.

- VoC Program output: If your organization conducts structured VoC surveys, then the outputs of such mechanism can be a good source of Continuous Improvement or Lean Six Sigma projects

- Customer Experience (CX) Dipstick: Customer Experience is usually hidden and not so obvious as customer feedback. Structured and unstructured mechanisms can be deployed to understand the customer experience. For example, many organizations now use mystery shopping to unearth issues in customer experience. Observation or Listening posts are also a good way to identify how customer experience can be improved.

- First Time Right (FTR): If you closely have a look at your company’s process, you will find that there are many internal defects (work-in-progress) occurring, such as rework, repairs & in-process rejections. Such defects are silent killers because they drain organization’s efficiency and effectiveness silently. If your organization is measuring FTR, then its improvement can be an ideal project. More evolved organizations use RTY (Rolled Throughput Yield) as a metric which is also a good place to demonstrate Continuous Improvement.

However, most organizations have a simpler measure of success for quality – Defect Rate (% Defective). While there’s nothing wrong with this metric, is a bit holistic and hence factors leading to inefficiencies escape unnoticed with this metric. Nonetheless, it is good starting point for Continuous Improvement projects. - Reliability Data/Warranty data: Field failures are sometimes grave. It can cost you a lot and, the overall cost of ownership for customers might increase esp if the warranty is denied or the product is under breakdown. In broader terms, the principle of warranty is to institute accountability in the event of an untimely failure of an item or the inability of the item to perform its intended function. Experts consider reliability data analysis as a quality measure over time. This reliability analysis is done to analyze whether your product will survive for the time defined by the company in the normal conditions. Improving the reliability of a product can work both ways – organizations can lower its operational cost and provide longer warranty and customers would experience break down less often.

- Process Performance Data: If your organization has a well-defined and structured reporting mechanism for process performance metrics, such as a dashboard or scorecard, then it would be a very good source to identify opportunities for continuous improvement projects. As leadership teams are consumers of such reports, such opportunities can easily gain sponsorship as well.

- Competitive Benchmarking: Benchmarking is a continuous process of comparing your firm’s or company’s practice to those of the competitors or say most successful competitors. In certain cases, you might not be doing well. For example, having control over the delivery time to the customers. Then this can be taken as a project for improvement in our company. So, to generalize, competitive benchmarking results can also be a good source for Continuous Improvement projects.

- Business Plans/Strategies: Gap between strategic plan and reality can be the cause of concern for leadership. Sometimes such problems may be because of supporting processes. They can hinder new business plans or strategies. Such process improvement opportunities are also a good source for projects, provided they are scoped well with well-defined objectives & goals.

- Employee Feedback: While customers don’t see your process but only experience its outcomes, employees have an end to end visibility. They experience problems as customers and can associate inward aspects of such poor experience. Many organizations, pilot their products with employees, because employees are pseudo customers. If you can establish a structured process through which employees are encouraged to share their experience and enable them to take up such opportunities as Continuous Improvement or Lean Six Sigma projects, there’s nothing like it.

All the above can serve as a good source for Continuous Improvement or Lean Six Sigma projects.

Tags

Tags

We talked about the need for Lean Six Sigma project selection in detail in the earlier articles, in this one we’ll cover the criteria for selection and the in the following article, we’ll move on to talk about the tools used for selection and how to engage the stakeholders in the process.

I have found that while leaders agree on the need for project selection, their views on the criteria is quite divergent. Most of them see this as a process to sway the process in favor of their priorities and interests.

There is nothing wrong in doing so, as long as the process is not biased.

Through this article, we draw consensus on the criteria and its relevance to the whole process.

The real good news is that the criteria for getting the project selection right are not too complicated.

What does project selection countdown look it? We’re going to start with the least of the top 5 criteria and find our way to the top most criteria.

Here you go:

7. Probability of Success:

Not all the projects will be successful in any company. Hence, while selecting the project, most project leaders consider the contingencies which might come up and use that as a yardstick to select the project. Sponsors want their project leaders to be successful equally as projects leaders’ desire success. Well, sounds like a good approach. But doesn’t this approach make it very orthodox? Unlike other implementation projects in technology, improvement projects are bound to have ups and downs; and it is quite natural that not all projects achieve their goals. That is what continuous improvement is all about.

Thus choosing to play it safe isn’t the best criteria to select projects, though unfortunately, it is very popular criteria in use. That is why Probability of Success is the last in our countdown list! One of the organizations flips these criteria to select the project which has failed in the past or have a low probability of success as Black Belt project. That is certainly a best practice to emulate.

6. Availability of Data:

Is data readily available for the project? If not, can it be easily gathered? While most project leaders and sponsors know that rarely will all the data needed for a project is waiting around to be analyzed. But they use the availability of data criteria to select projects because the unreasonable expenditure of time, resources and effort can be avoided. Yes, data is needed for analysis. But making it a criterion reduces the scope Continuous Improvement deployment.

Improvement projects are expected to venture into unchartered territories of the process and present root cause and opportunities. Getting people to measure something that is not being reported till now, in it is a feat. Having vanilla project can hardly be a criterion for project selection. That is why the availability of data comes second last in our countdown!

5. Savings potential:

Any project implemented, is implemented with an intention to gain any kind of tangible or say monetary benefits. But along with monetary benefits, there are other benefits like customer satisfaction, increased efficiency, total company involvement; increases workspace and much more. While it is absolutely apt to select projects which have savings to the organization, it is misleading to make saving potential a primal purpose of projects. I have seen many times, project leaders come up with simple ideas or improvements with a huge saving potential to the organization, but virtually no complexity involved. Such projects hardly qualify for Black Belt projects.

They best serve as Just Do It project. Giving undue importance to saving potential in project selection also sends the wrong message across the organization. That is why I not really excited about having this as a top item in the countdown. That’s why Saving Potential is only Number 5 in our countdown.

4. Apt Time:

There is always a perfect timing to initiate a project. Relevance is contextual. By apt timing, I mean both the time to commence, and the closure as per plan. An important project has to close on time. It has to be first of all, planned to close on time. It has to be scoped to close on time. That is why Apt Time is No.4 in our countdown.

3. Availability of Resources:

I don’t know if this has to do with the culture. Most organizations, if not all, end up with a laundry list of projects because everything seems to be Business or Customer priority. Even the biggest and richest of the organizations have limited resources. Either resource is depleted, busy elsewhere or simply not committed to deliver. The best person is often leading many projects, making everything he/she does venerable to failure. Project selection is about de-selection and not selected. Ruthlessly put ideas into a parking list for which right resources are not available; and if it is so important that it has to be executed now, then pull the right resource into this project rather than sharing.

While I have largely kept this point around manpower, it equally applies to money & time. I say with conviction that organizations that ensure that the leader of the Lean Six Sigma project is a dedicated resource, either full time or handling only one project even if it means he is part time on it are surely successful. This is why Availability of Resource is No.3 on our countdown!

2.Customer impact:

Ask yourself “will the results of the project bring any difference in the life of the customer? Will it improve the perception of the customers about the quality of your product or services?” Quite often this answer to this question is yes. Unfortunately, it’s motherhood in apple pie question. So insist on quantifying the impact.

If you can pin a number to the impact, then go ahead. And if you’re not able to do so, then there’s no point in wasting your time on the project. Consider Voice of the Customer in your organization as a starting point. Why don’t you start with complaints and alleviate customer pain? Thus Customer Impact is Number 2 in the countdown.

1.Business Priority:

Selection of projects is based on the need or priority of the business. Project leaders need to understand that the tail can’t wag the dog. Often, people package their ideas into a project and fuel it as an organizational priority. Scanning of the external and internal environment will give first-hand insight on what is the organizational priority, NOW? Go for it. Well, that may put you out of your comfort zone, competency or expertise, but remember that’s what the organization needs.

Without a real need, do you think any leader would offer sponsorship to your project or will it at all help anyone – NO.? That is why Business Priority is Number 1 in our countdown.

Project Selection and implementation of Lean Six Sigma is easy and at the same time should be handled delicately by keeping all the above aspects in mind otherwise it might turn into a big disaster. An effective diagnostic study is required before selecting projects and with the undivided involvement of the top management are pre-requisites for project selection.